The first step in controlling wood dust is to capture it at the source. A typical shop will have a shop vacuum and a dust collector with its duct work, collection hoods and filters. Many shops will also include a wood chip Seperators. The following article discusses how I worked with each of these to improve my dust collection system.

Capturing Woodshop Dust at the Source

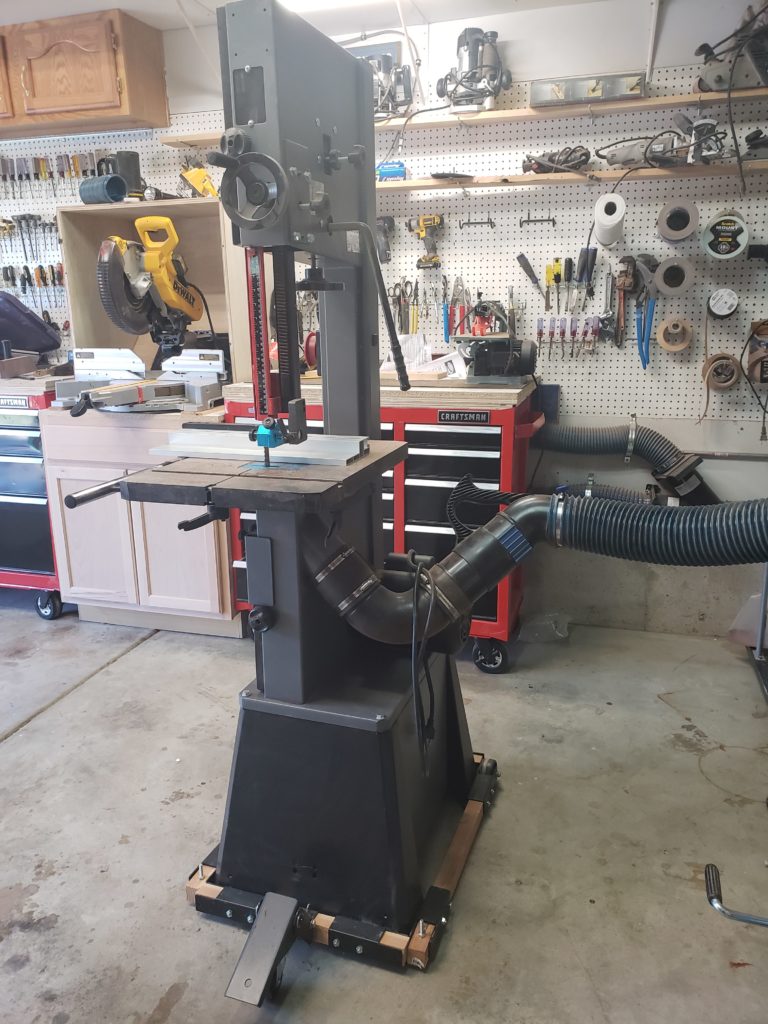

Take a few minutes and study this picture. You will see two pieces of equipment

that throw dust all over the shop, the lathe and the miter saw. Although I tried,

both of these tools are very hard to effectively connect to the dust collector in the back

corner.

I also have a belt sander, a planer, a drill press and a drum sander connected to the

dust collector that are not shown in the picture. Each of these tools were also creating

significant amounts of dust that was not being effectively captured by the dust

collector. The sanding table shown on the right didn’t work well either.

My continued breathing all of this dust resulted in some significant health problems, so I desperately need to make some improvements to this dust collection system or quit working in my shop altogether. The following are some details of improvements to this dust collection system that I desperately needed to make.

Shop Vacuums

Like most of us, I started woodworking in a with a few hand tools and a couple of power tools. I tried to catch some of the wood dust at its source by connecting a shop/vac to the power tool. This worked well with the hand-held tools like my sander, but not with my table saw or my miter saw.

These larger power tools were throwing woodchips and dust across a wide area of the shop. The wet/vac couldn’t capture it all.

Industrial Inc.

Even when I tried to confining the dust with a dust shield the wet/dry vac couldn’t keep up. The wet/dry worked well with small dust shields like the one on top of this table saw. But not for larger tools like belt sanders or miter saw. These tools require larger dust shields that don’t work well with a Shop Vac. These large dust shields need must have a lot of air moving through them and a wet/vac cannot do that. While small dust shields work fine moving less high pressure air, if their intakes are close to the dust.

Think of it this way: If you have a big dust port on the end of your vacuum cleaner’s hose you’re not going to pick up much dust. You need to have the end of the hose closer to the dusty floor or you need to have a larger hose connected to a more powerful machine, like a dust collector, that moves larger volumes of air.

Dust Collectors

The suction capacity of a Shop Vac is less than 200 CFM (cubic feet per minute). On the other hand, the suction capacity of my Central Machinery 2 HP wood Dust Collector is about 1500 CFM. When I purchased it, I didn’t need to know the difference between air flow and air pressure, it just seemed reasonable that since my large power tools were creating more dust than my handheld tools, they needed a more powerful vacuum to collect it. Besides, most of those tools have a 4-inch dust port, that connects to a dust collector not a Shop/vac.

I purchased the Central Machinery wood dust collector hoping it would solve my dust problems, but it didn’t. I was still not collecting all of the woodchips and dust. The hoses were clogging with woodchips and fine dust was still filling the air in the shop and covering shelves and other surfaces around the shop.

Cyclone Wood Dust Collectors

My first thought to improve the dust collection was to purchase a larger cyclone style dust collector. These machines have more power, better filtering and come with a chip collector to keep the impeller from clogging. But they are larger than my Central Machinery wood dust collector and they are expensive too. Cyclone dust collectors work well for large shops, or professional shops with a lot of complex ductworks. Shops like these have more machinery than I have, and I didn’t have the necessary space for this large of a dust collector, so I chose to keep my dust collector and find other alternatives to improve things.

Duct Work

Even though my dust collector is rated at 1500 CFM this number represents the airflow before anything is connected to it. After connecting my flexible ductwork to each tool, it was easy to tell that the suction at the tool connection was far less than the suction at the intake of the dust collector itself. It was easy to tell that with every connection, blast gate and every inch of hose, I lost more suction. I also found that the ripples in the flexible duct work creates friction, and this friction slows the airflow.

I considered replacing all of the flexible ducts with PVC but there wasn’t much that I could replace. Most of my tools are on wheels, so they need flexible hoses to allow them to move.

The blast gates, T, Y and elbow connectors create friction that slows airflow clog with dust and wood chips.

To solve this, I replaced most of the ductwork, Ts, Ys and elbows with a Dust Rite quick change handle. This eliminated unnecessary ductwork and increased the airflow by moving one hose from tool to tool.

Wood Chip Separators

The Dust Rite quick change handle increased airflow by eliminating most of the connections and a lot of the flexible ductwork, but I was still having issues with woodchips clogging the impeller and the filter of the dust collector.

A cyclone dust collector would eliminate this problem by separating the large woodchips from the fine dust. But since I decided against the purchase of one of these machines, I settled on a cyclone dust separator.

Cyclone Wood Chip Separator

The less expensive alternative to a cyclone dust collector is a cyclone dust separator like this trash can style that I use. There are several cyclone woodchip collectors on the market so there could be better alternatives than this, but this one is doing a good job for me. All the woodchips and dust are vacuumed into this dust separator before reaching the dust collector. The woodchips fall to the bottom and the fine dust is collected by the filter in the dust collector. This help prevent the large particles from clogging the impeller and the filters, and it makes it easier to dispose of the waste.

This top to this cyclone collector is available from Woodcraft and the metal trash can was purchased from Home Depot.

Wood Dust Filters

Weather it is a shop-vac, a cyclone collector or a standard wood dust collector, the machines filters are the last chance to prevent the small dust particles from reentering the air you breathe.

One problem with all filters is they begin to fill with the dust. As that dust collects in the filter the airflow of the system begins to decrease, this reduces the amount of additional dust that the system actually collects.

Another problem is differences in airflow among the various types of filters. Again, my dust collector’s airflow is 1500 cfm., but this measurement is without any duct work, dust bags, air filters or any other attachments. The need for replacing my dust bag and air filter turned out to be one of the most difficult parts of the dust collection system for me to understand. This is because many of the companies that manufacture these filters don’t tell us the efficiency and airflow of the filters they make. Worse yet, they don’t all use the same rating systems, making it difficult to compare one filter to another.

The old filter bag on my collector was not one of the newer five-micron filter bags. These five-micron bags are better than the old ones because they supposably filter out dust particles that are five-microns or larger. The question I have is, how many of these particles do they actually filter out? 50%, 75%, or all of them? They don’t tell you.

One the other hand, most canister filters use standardized Minimum Efficiency Reporting Values, or MERVs, to report a filter’s ability to capture particles between 0.3 and 10 microns (µm).

In any case, I had to replace my filter bag because fine dust was being released into the air through the one that was currently on my dust collector. I chose to I used a canister filter for my replacement because it had a better filtering capacity than the new five-micron bags and it also had a larger service area, so it doesn’t reduce airflow as much as a bag filter does.

Specialized Wood Dust Collection Hoods

Most of the larger power tools like the planer, band saw, and belt sander shown above are built to contain the saw dust for the dust collector to easily collect. On the other hand, there are tools like this miter saw that tend to through dust all over the shop. In part three of this series, I will provide the free plan for this miter saw station and a sanding table that helps prevent the sawdust from your handheld sander from entering the air.