My Health Problems Started with Headaches, Coughing and Dizziness.

Sudden coughing attacks, constant headaches and dizziness plagued me every time I went into my shop. My health continued to get worse and cramping in my back made it impossible to work for any length of time. Also, the wood dust made me sick; I developed COPD and several other health problems from breathing the wood dust. I needed to improve my dust collection systems, and to make things worse I had a bad habit of not wearing a dust mask.

Unfortunately, I developed COPD and several other health problems from breathing wood dust,

Dangers of Breathing Wood Dust

Below is an example of a woodturning I from spalted pine, wenge, and Inlace. Each of these have the potential for causing health problems:

Spalted woods may contain fungus spores. Pieces of ground up fungi can cause an inflammatory or an allergic response in many people.

Inhaling Wenge and other exotic wood dusts can cause breathing and central nervous system problems.

Products like the Inlace in this vase, may contain metallic dust, stone flakes, pearlescent dyes, solid color dyes, and resin. Many of these may be carcinogenic and present other dangers to your health, especially when inhaled.

See the Island Woodturners Guild for more information on wood toxins: Island Woodturners

Find More Space and Keep Your Air Clean.

After two years and a lot of medical expenses, I am well enough to work in my shop again. But first, the dust collection system needed to be fixed. This will be the first in a series of posts detailing the improvements I made, starting with rearranging my shop.

For more about my health problems and the dangers of breathing wood dust click here: https://artisticfirewood.com/a-response-to-my-beautiful-death/

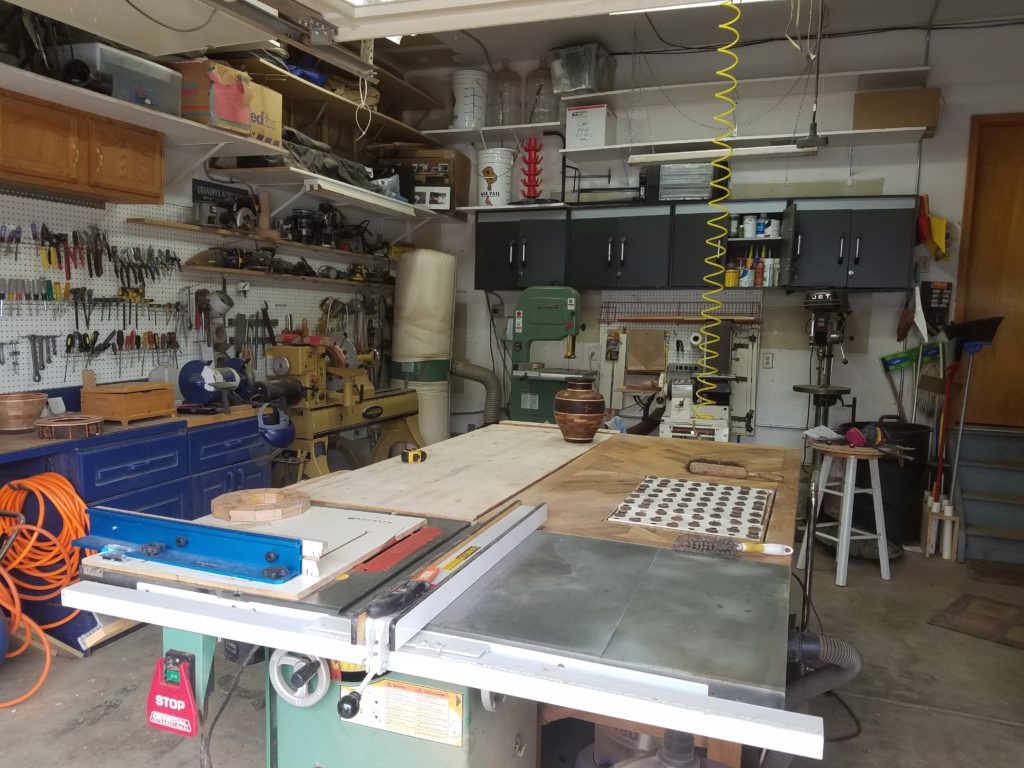

The Shop Layout Before:

When I started to redesign my shop, all of my tools were crowded into the single car side of a three-car garage. Solving the dust problem was goal number one but I also wanted to leave the tools in place because they are easy to work with.

Workbenches became cutoff supports behind the table saw with a downdraft panel built into the workbench on the right to collected sanding dust.

My belt sander, drill press, planer and bandsaw on wheels rolled up against the back wall. With them there, I connected each to the dust collector through a system of flexible vacuum hoses and moved them away from the wall when in use.

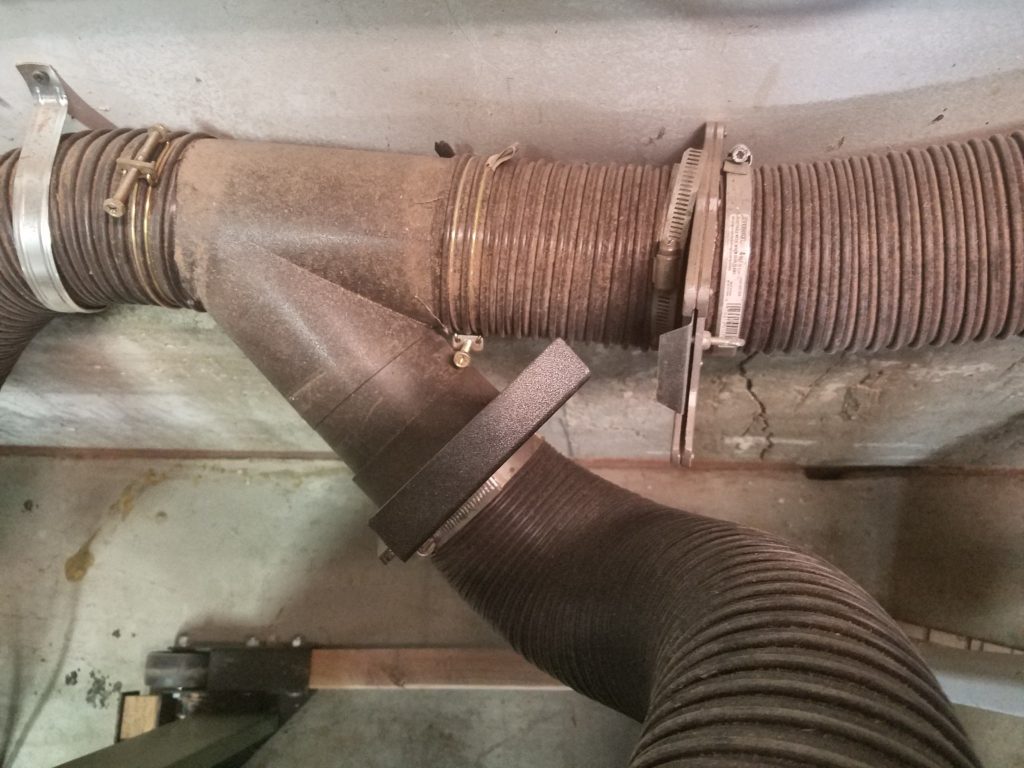

The dust collection system used long flexible vacuum hoses, several blast gates and multiple Y connections creating resistance that reduced airflow to the dust collector.

The dust collector used older style filter bags that let fine dust particles escape back into the air.

my main workbench is built from solid maple and under it are two tool cabinets with a total of nine drawers. The plans for this workbench and the tool drawers are available from FineWoodworking.com.

My lathe and miter saw on the left wall are connected to the dust collector through the system of vacuum hoses, but they still throw dust into all corners of the shop making it very difficult to clean.

The Shop Layout After:

Rearranging the shop was not the plan, only improving the dust collection. However in the middle of the project, I purchased a new car and I didn’t want to leave it in the driveway.

A refrigerator, the lawn mower, rakes, shovels and trash containers filled the double side of the garage leaving it too crowded for both cars. The shop was packed into the single car side of the garage so, again, no room for the new car there either. Therefore, the only solution was to rearrange everything, redesign the dust collector’s vacuum lines and add some additional equipment.

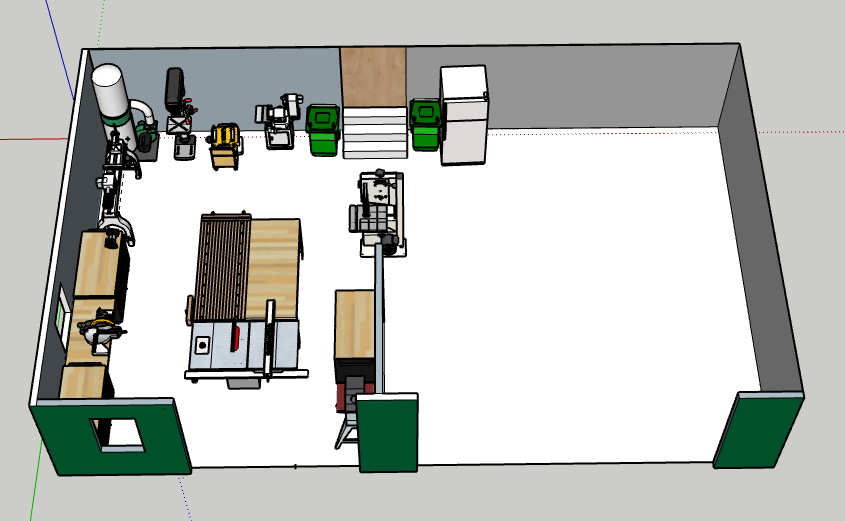

The diagram above shows the moves I made and below is a summary of those moves:

- Several tools and the workbenches moved to the two-car side of the garage.

- The lathe moved out of the back corner of the shop and attached to a vacuum duct with a line to the dust collector.

- A new miter saw station built from two tool chests and a kitchen base cabinet.

- A dust hood built for the miter saw to keep the dust contained for the dust collector.

- The entire system of ductwork redesigned, and a cyclone chip collector added.

- A canister style filter and a plastic dust collection bag replaced filter bags on the dust collector.

- A portable dust collector added to my other dust collection equipment.

In future posts find details on each of these changes along with more hints for capturing dust, including plans for the downdraft table, miter saw station and the dust hood.

Improved Shop Dust Collection (part 2)

Ever wondered what the differences between N95, P95 and P100 masks are? Improved Shop Dust Collection (part 2) starts this series of articles with a complete guide to dust masks and respirators.